The Advantages and Disadvantages of Stepper Motors

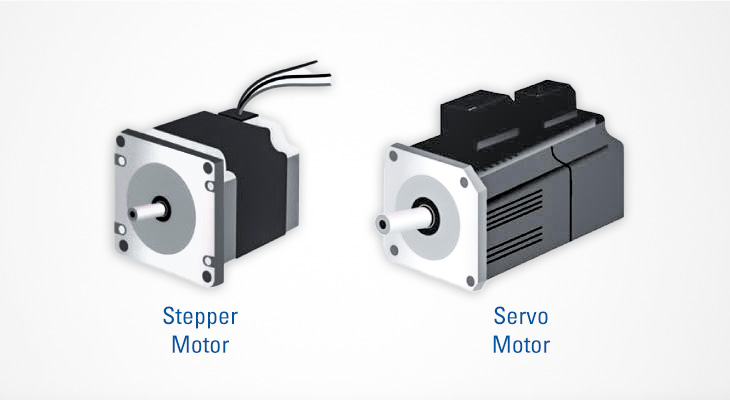

This lesson is a continuation of a series of lessons involved with learning about Stepper Motors and Servo Motors. If you haven’t already, please review our previous lesson on, What is a Stepper Motor and How it works. In this lesson, we will discuss the Stepper Motor Advantages and Disadvantages compared to Servo Motors.

Have you ever thought about how a robotic arm moves with precision, how graphics printers create accurate replications of images, or how consumable products are moved precisely around a plant floor or any other type of motion-control positioning system? Together with the recently RealPars published video, What is a Stepper Motor and How it Works, and this lesson, you will learn about Stepper Motor Advantages in motion control when using different types of motors available, primarily stepper and servo motors.

Selecting between a stepper motor and a servo motor can be quite a challenge. The balancing of several design factors in cost considerations, torque, speed, acceleration, and drive circuitry, plays a vital role in selecting the best motor for your application.

What is A Stepper Motor ?

A stepper motor is one of the most common motors used in motion control applications, primarily positioning applications. Even though they usually operate open-loop, that is, without using feedback devices like encoders or resolvers, they can be accurately controlled, down to fractions of a degree, which helps reduce the cost of systems.

Advantages of Stepper Motors

- Relatively low cost and availability

- Flexibility

- Easy to set up

- High Torque Requirements

- Safe

- Longer Life

- Low Torque Speed

- Excellent Repeatability

- Precise Positioning

- Great for constant load applications

- Reliable

- Low Maintenance

- Works great in many environments

Disadvantages of Stepper Motors

- Low accuracy

- Sometimes very noisy

- Low efficiency

- Not easy to operate at high speeds

- Stepper motors cannot run or rotate at high speeds

- Vibration

Helix Linear Technologies offer a variety of different stepper motor linear actuators including captive, non-captive, external, and ball screws. Our lead screws are securely press-fitted into the motor’s rotor to allow a smaller footprint while minimizing backlash and providing years of dependable life. Contact one of our engineers today to learn more about stepper motors.