Top 10 Benefits of an Electric Linear Actuator

When selecting linear actuators for motion control applications, engineers can choose from various electrical (electro-mechanical), hydraulic or pneumatic technologies. An electrical actuator will prove to be the better choice in nearly all cases due to a unique combination of characteristics.

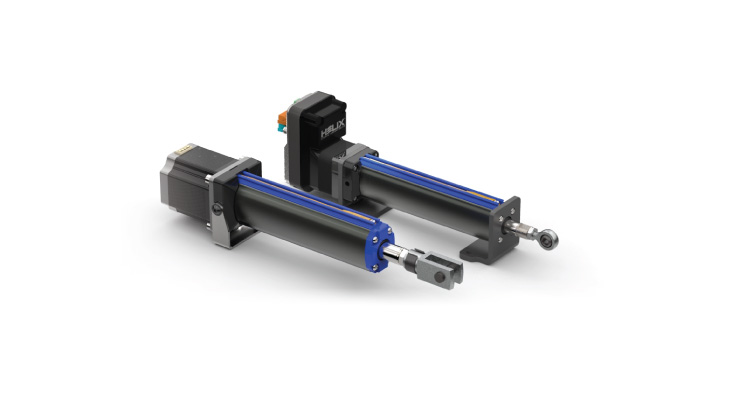

Characteristics of Electric Linear Actuators

1. Simplified Design

Hydraulic and pneumatic actuators can have many more parts within their system than an electrical actuator, and they can be much more complicated to incorporate into your design. The more straightforward design of electrical actuators results in savings in terms of design and maintenance because of lower initial and ongoing costs, higher reliability, and fewer spare parts to stock in the case of needed repairs.

2. Easy Integration with Other Systems and Equipment

It is much easier to integrate an electrical linear actuator with the microprocessors and programmable controllers that manage the operation of most modern industrial machinery than to integrate either a hydraulic or pneumatic solution.

3. Higher Precision Compared to Hydraulics and Pneumatics

Electrical actuators provide a much more acceptable level of control throughout the entire motion process enabling the force, speed, and torque to vary at different stages during the motion. This capability helps reduce operating costs and increase throughput by reducing the number of equipment changeovers required during a processor for product changeovers in manufacturing.

4. Increased Safety

Hydraulic and pneumatic systems are typically under constant pressure and can rupture and leak, even when well maintained, posing an environmental safety concern, especially in food or medical processes. Leaked hydraulic fluid is a magnet for dirt and contamination. Not only is this dirt detrimental to product quality, but it may also cause more frequent equipment failures, resulting in lost time, reduced throughput, and higher costs. Clean electrical linear actuators help keep workers and products safe from contamination.

5. Lower Costs

An electrical actuator often costs less than hydraulic or pneumatic actuators with similar capabilities. Even if the initial acquisition cost is equivalent, electro-mechanical actuators cost less to maintain, are easier to install, and are rugged and reliable for use in almost every environment. Electrical actuators can support the positioning of the load even without the continuous application of power, so they can be much less expensive to operate. In contrast, pneumatic actuators require a constant flow of air pressure and a compressor that runs continuously to maintain a load. As stated previously, both pneumatic and hydraulic actuation systems are subject to leaks and hose failures under pressure.

6. Easier Assembly

It is much easier to connect wires and cables than to connect hoses and pumps. Hence, the assembly process becomes simplified with electrical actuators than with either pneumatic or hydraulic devices. The more detailed assembly process results in higher quality output, reduced labor costs, and more reliable equipment performance.

7. Smaller Footprint

Because of the smaller number of components, electrical actuators usually have a smaller footprint than either hydraulic or pneumatic actuators with similar capabilities. The smaller size results in overall designs that are more compact and provide more flexibility concerning incorporating the actuator in the general application or design.

8. Quieter

There's a reason that pneumatic actuators are nicknamed "bang, bang" or "click, clack" devices. They essentially have two stops, and the device usually emits a noise at each end of its motion spectrum as it bumps into its mechanical stops. On the other hand, electric actuators use quiet electrical motors to control the motion, so they are more suitable for any application or device, but especially for devices destined for medical or health care facilities, HVAC systems, or rail and automotive applications.

9. Cleaner

Pneumatic devices rely on compressed air, and any failures may blow contaminants into the environment. Hydraulics may leak and contaminate the product or the area and endanger workers. An electrical actuator uses only clean, efficient, and safe electricity to operate.

10. Increased Flexibility and Synchronization Options

An electrical actuator provides the application designer or end-user with flexible parameters often easily set with a simple interface from a PC or other device, allowing more design flexibility in a smaller footprint. In addition, these parameters may enable the device to synchronize with other equipment in an assembly line or production operation, providing the promise of smoother, more efficient operations with less inventory buildup between operations.

While hydraulic and pneumatic actuators may have their place in specific applications, most engineers will find that clean, safe, quiet, flexible, and economical electrical linear actuators are a better choice for most applications.