FAQ Friday: The Top 4 Questions About Slide Systems

f you've ever wondered about the construction of slide systems and their functions, scroll below to read the top four most frequently asked questions.

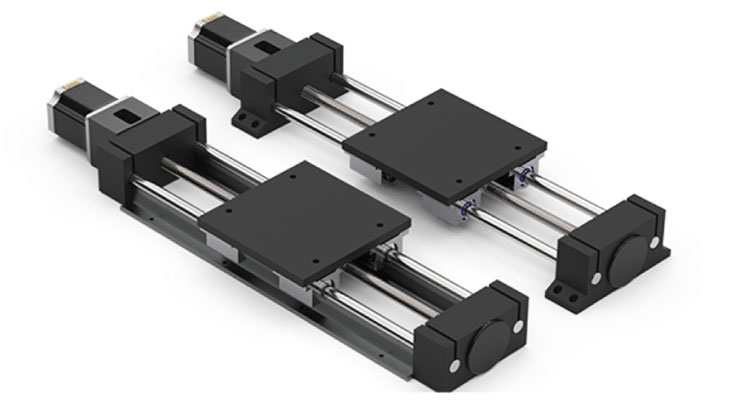

1. What are Slide Systems?

A Helix Linear slide assembly is genuinely a "System," not just a "Component." The matched components used in Helix Slides result in better system performance. When Helix Linear Slides Systems are used as sub-assemblies setup and alignment time is reduced. Helix Linear Slide Systems are easier to specify and to order. Precision carriage plates supplied with Series 100 and 200 help prevent misaligned shafts and bearings. Aluminum carriage plates include threaded steel inserts at key mounting locations—the protective, non-corrosive finish on all exposed non-wear components.

2. What Type of Lubrication Should Be Used on Ball Bushing Bearings or Linear Systems?

Helix recommends and offers linear bearing lubricant LBL-1 which is synthetic–based oil with PTFE. It is sold in 4 oz bottles (NLU-1006) or a 12 bottle case (NLU-2006)

3. What Can Helix Slide Systems Do?

Helix Linear Slide Systems are designed to be used in the following applications:

- Product Packaging

- Electronics Manufacturing

- Food Processing

- Machine Tool Equipment

- Component Assembly

- Material Handling

- Converting Processes

- Container Manufacturing

- Medical Equipment

- Textile Industry

- Automated Test Equipment

4. Can Slide Systems Be Modified?

Contact Helix Linear to discuss particular requirements. Modifications for linear slide systems include:

- Special screws (ground thread, precision rolled with preloaded nuts, high lead

- screws, metric lead screws, etc.)

- Protective boots in a variety of materials (neoprene, metallic, etc.)

- Special motor mounts with Servos motors, steppers motors, and drives

- Custom carriage machining